Robot Dexterity

Backed by £57m, this programme aims to transform robotic capabilities and unlock a step change in human productivity.

Our goal

To release the bottlenecks in robotic dexterity and create vastly more capable and useful machines.

Why this programme

Breakthroughs in AI are transforming robotic abilities, but the development of robot bodies has not kept pace with advances in computation. Robots cannot achieve the flexibility, speed, and precision of human manipulation, rendering them useless for many of the difficult or dangerous tasks where we need them most.

The need to improve robot dexterity comes at a critical time. The proportion of the world’s population aged 65+ is expected to triple by 2100, while labour deficits for physically demanding work are set to increase. Robots have the potential to ease these labour shortages and boost prosperity but to do so, we must close the gap between what robots and humans can handle.

What we’re shooting for

We’re funding an array of cutting-edge research across robot hardware and advanced simulation, with the ambition to usher in a new era of dexterity.

"Breakthroughs in AI are poised to make robots far more flexible and capable of helping with the dull, dirty, and dangerous tasks that humans don’t want to do. But robotic bodies are lagging behind. This programme aims to catalyse advances in robot bodies, ultimately enabling them to handle objects with the skill and dexterity that humans do."

Technical Areas

This programme is split into three Technical Areas (TAs), each with its own distinct objective:

Novel Hardware

Focuses on innovative components and new approaches to designing and building hardware to enable dexterity.

Socioeconomic Considerations

Focuses on exploring the socioeconomic considerations of increased automation enabled by robot dexterity.

Modularity, Interoperability, Common Standards

Focuses on facilitating modularity, interoperability, and some common standards within robotics.

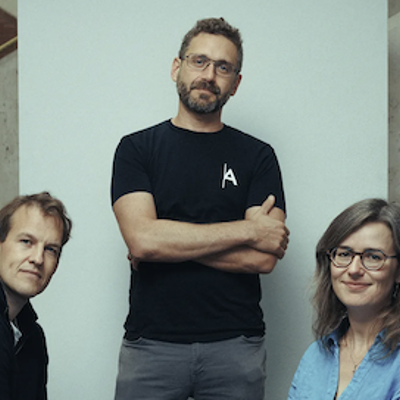

Meet the programme team

Our Programme Directors are supported by a Programme Specialist (P-Spec) and Technical Specialist (T-Spec); this is the nucleus of each programme team. P-Specs co-ordinate and oversee the project management of their respective programmes, whilst T-Specs provide highly specialised and targeted technical expertise to support programmatic rigour.

Jenny Read

Programme Director

Jenny Read is a visual neuroscientist, previously trained in theoretical astrophysics. Her work focuses on how we can build smarter bodies for robots through new modes of sensing, transmission of sensory information, and actuation through hardware advances. Jenny joined ARIA from her role as Professor of Vision Science at Newcastle University.

Paul Brown

Programme Specialist

Paul joined ARIA from a project management role at a global market research company. He previously worked on delivering the COVID-19 vaccination deployment programme. Paul holds an MSc in Environmental Technology from Imperial College London and a BSc in Geography from the University of Exeter. Paul supports ARIA as an Operating Partner from Pace.

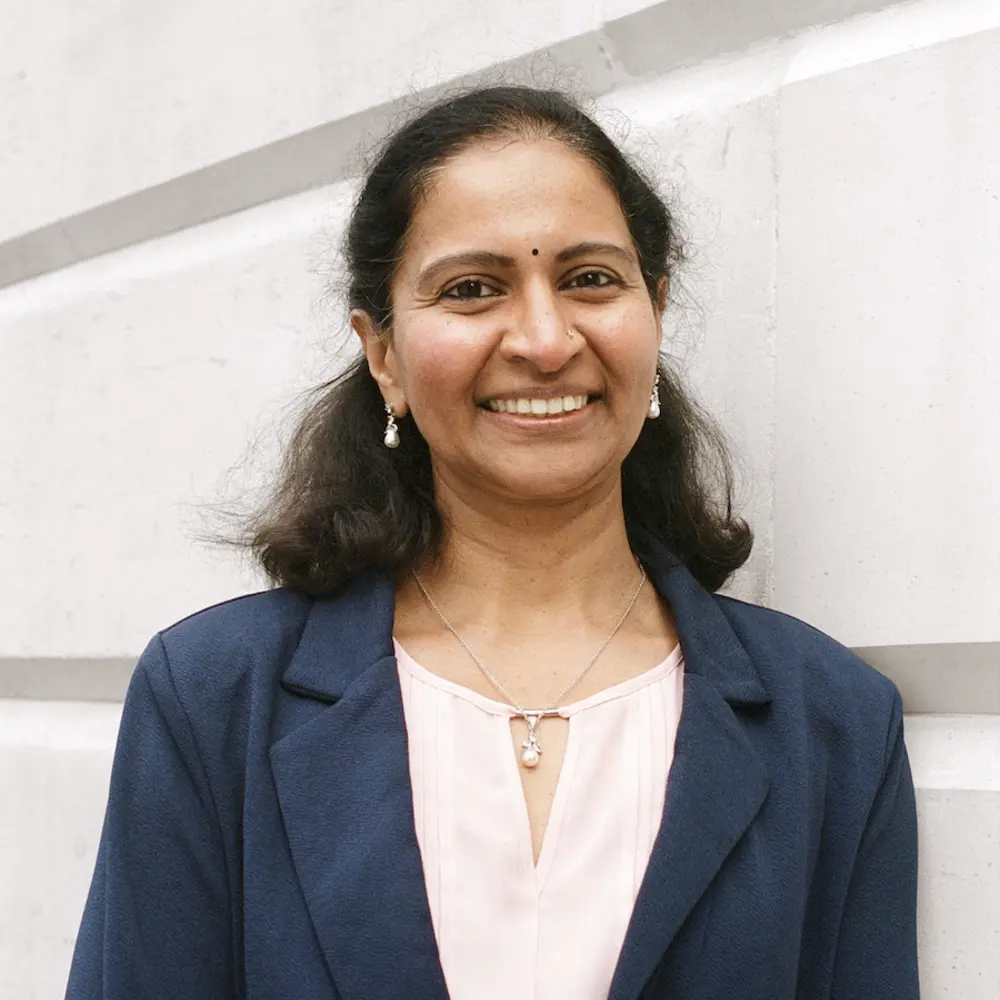

Radhika Gudipati

Technical Specialist

Radhika has fifteen years in the robotics industry and is passionate about entrepreneurship, laboratory automation, and sustainability. She works between engineering and user perspectives, drawing from her roles at Ocado Technology and Shadow Robot, where she focused on robotics research and business solutions. Radhika holds a PhD in robotics for healthcare from the University of Hertfordshire.

Featured insights

Sign up for updates

Stay up-to-date on our programmes and opportunity spaces.

Programme Directors

Our Programme Directors are exceptional scientists and engineers with the curiosity to explore uncharted territory

How we work

We seek out exceptional scientists and engineers and empower them with the resources and autonomy to turn their ideas into reality